Dave Clark has instructed Machine Technology at Barberton High School for 13 years. Prior to that, he’d been trained as a moldmaker: a skilled tradesman crafting molds for use in casting metal products and parts. Through his career, Clark rose to manage operations for machine shops. His is a rich experience of both industry knowledge and teaching.

Dave Clark has instructed Machine Technology at Barberton High School for 13 years. Prior to that, he’d been trained as a moldmaker: a skilled tradesman crafting molds for use in casting metal products and parts. Through his career, Clark rose to manage operations for machine shops. His is a rich experience of both industry knowledge and teaching.

“When I talk to people in the trades today, I hear them saying they want so many more young people coming from programs like ours: there is a big demand in manufacturing.”

Clark is referring to the Four Cities Compact in North Central Ohio, where four high schools share in providing career and technical education to students: Barberton High School, Copley High School, Norton High School and Wadsworth High School. Students have access to 18 different pathways, including Programming, Design and Robotics; Machine Technology; and Engineering Design and Technology. The Four Cities Compact schools are part of the SME PRIME® (Partnership Response in Manufacturing Education) schools network.

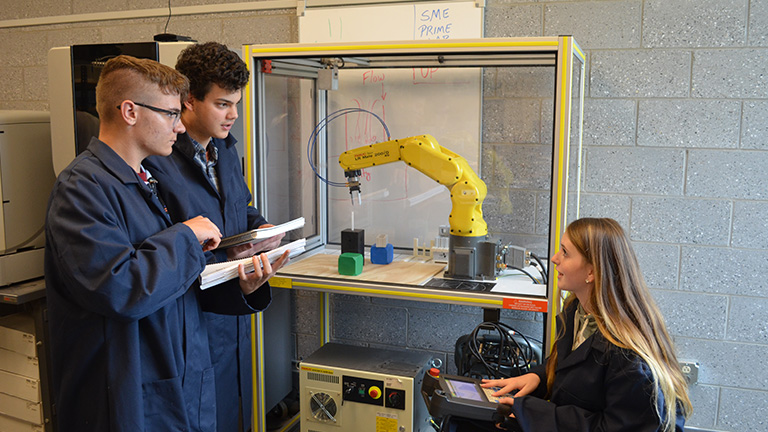

McKenzie Jarnigan, recent graduate of the Honors Engineering program of the Four Cities Compact, notes that the pathways available through the Compact and SME PRIME offer choices and exploration for every student. “I’ve always enjoyed messing around with electronics, and I want to get deeply into mechatronics and robotic programming,” says McKenzie. “There are a lot more girls starting to become interested in this – and I think it will grow.”

McKenzie Jarnigan, recent graduate of the Honors Engineering program of the Four Cities Compact, notes that the pathways available through the Compact and SME PRIME offer choices and exploration for every student. “I’ve always enjoyed messing around with electronics, and I want to get deeply into mechatronics and robotic programming,” says McKenzie. “There are a lot more girls starting to become interested in this – and I think it will grow.”

The Compact, with its partnership with SME PRIME, is committed to inspiring students and creating awareness of opportunities in industry – and preparing them to pursue those opportunities. Students have access to relevant curricula, modern equipment and qualified, engaged instructors like Dave Clark.

Brooke Christie, another recent graduate, had seen a lot of friends go through Four Cities Compact programs, and felt that it was it was head start on a good career.

“I’ve learned how to work with lathes and mills; I like it a lot,” said Christie. “I’m hands-on; I like to work on things, make things.”

Brooke has prepared for and will soon begin an apprenticeship in machine maintenance at Schaeffler Group USA. Schaeffler is a global manufacturer and supplier of high-precision components and systems in engine, transmission, and chassis applications, as well as rolling and plain bearing solutions for industrial applications.

Brooke will be the very first female apprentice in machine maintenance at Schaeffler’s Wooster, Ohio facility. Not without coincidence, Brooke’s sister (also a graduate of the Machine Technology pathway of the Four Cities Compact/SME PRIME program) is the facility’s first female tool and die maker.

Brooke will be the very first female apprentice in machine maintenance at Schaeffler’s Wooster, Ohio facility. Not without coincidence, Brooke’s sister (also a graduate of the Machine Technology pathway of the Four Cities Compact/SME PRIME program) is the facility’s first female tool and die maker.

“She’s a leader,” said Dave Clark of Brooke. “And she’s got a great future.”

Read Part 1 – The Four Cities Compact: Schools Collaborate to Provide Opportunity