The fourth industrial revolution is upon us with advanced robotics and automation technology spreading throughout manufacturing operations in the United States and abroad. The next-generation of manufacturing workers require a different array of skills within the workplace than previous generations. SME Education Foundation Student Summits introduce and enhance awareness of important skills like critical thinking, complex problem solving, people management and collaboration in advanced manufacturing.

The fourth industrial revolution is upon us with advanced robotics and automation technology spreading throughout manufacturing operations in the United States and abroad. The next-generation of manufacturing workers require a different array of skills within the workplace than previous generations. SME Education Foundation Student Summits introduce and enhance awareness of important skills like critical thinking, complex problem solving, people management and collaboration in advanced manufacturing.

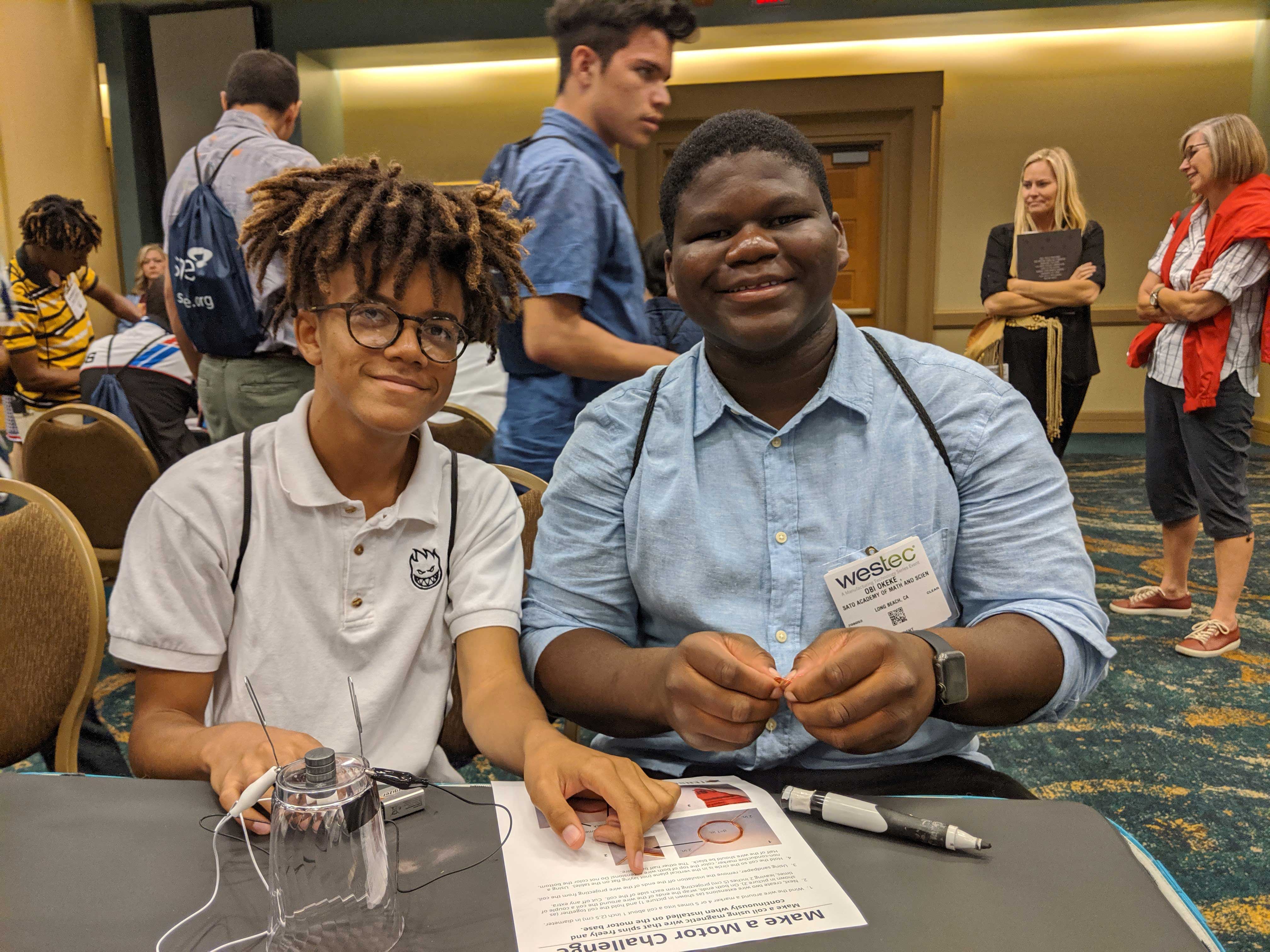

The World Economic Forum report, The Future of Jobs, discusses the workforce strategy of the future, focusing on employment and the skills needed to be successful in today’s manufacturing operations. Skills like creativity, critical thinking and collaboration were key to the 2019 WESTEC Student Summit Racing Challenge. The Racing Challenge winning team from Sato Academy of Mathematics and Science in Long Beach California, says working in groups is very critical for achieving a high level of productivity and winning the manufacturing competition. The team also pointed to the importance of members knowing their roles, which became crucial when splitting up large groups into smaller groups.

“My biggest takeaway from the WESTEC student summit challenge was that working in groups is very crucial for productivity; it’s also very helpful to breakup into sub groups within the bigger group,” said Obiora Okeke, a junior at Sato. “Because then you don’t have too many people working on one thing and then you could have, like, two people working on the CAD (Computer-aided design), while the other two of us worked on the science experiment with the metal wire.”

Tobias McIntosh, also a junior at Sato, added that everyone in the group are good friends and work together on a lot of projects during the school year. “We know each other’s strengths and weakness, and during the competition we focused on taking advantage of those strengths and weaknesses in the subgroups that we formed.”

Tobias McIntosh, also a junior at Sato, added that everyone in the group are good friends and work together on a lot of projects during the school year. “We know each other’s strengths and weakness, and during the competition we focused on taking advantage of those strengths and weaknesses in the subgroups that we formed.”

The high school students from Sato Academy also toured the expansive show-floor of WESTEC exploring the different types of manufacturing companies exhibiting at the event.

Noah Gregory, a junior at Sato, was taken aback at the complexity and specialized nature of the manufacturing equipment and technology on display at WESTEC. “Every single thing we saw was completely specialized. There was a booth dedicated to springs and others that were for different tools and machines that use those tools. Honestly, it was just insane.”

Tobias was excited to see a company that manufactured dry linear bearings. “I really like that company, because I purchase dry linear bearings for my 3D printer at home. I just thought it was really cool to how this company also used dry linear bearings and how they are utilized within the manufacturing industry.”

The students also visited a company that tested parts. “They tested the metal that I got from one of the laser companies on the tour,” said Tobias. “They laser cut a piece of metal for me and they told me that it was a piece of steel. So, we tested the metal and this company was able to verify that it was actually steel. So, that was awesome.”

SME Education Student Summits encourage participants to utilize the knowledge and experience from their classroom learning and apply them to the racing challenge competition. Sato Academy students utilize Vex Robotics parts to learn the coding necessary to have their robots perform certain tasks.

“I think that's one thing that showed up a lot during the competition, with someone putting in a certain amount of information and then the machine actually doing that,” said Jayce Ferris, also a junior at Sato. “And, in previous years we've had used different CAD programs, so I think that really helped in the CAD part of the competition. Because we had a basic understanding of how that software works. Even if we don’t know where every button is, we were able to figure it out.”

“I think that's one thing that showed up a lot during the competition, with someone putting in a certain amount of information and then the machine actually doing that,” said Jayce Ferris, also a junior at Sato. “And, in previous years we've had used different CAD programs, so I think that really helped in the CAD part of the competition. Because we had a basic understanding of how that software works. Even if we don’t know where every button is, we were able to figure it out.”

That’s what the SME Education Foundation Student Summit event series and the manufacturing competition is all about: Inspiring students to see the opportunities available to them as they continue to practice the skills they learn daily in their classrooms.